Oct 04, 2025

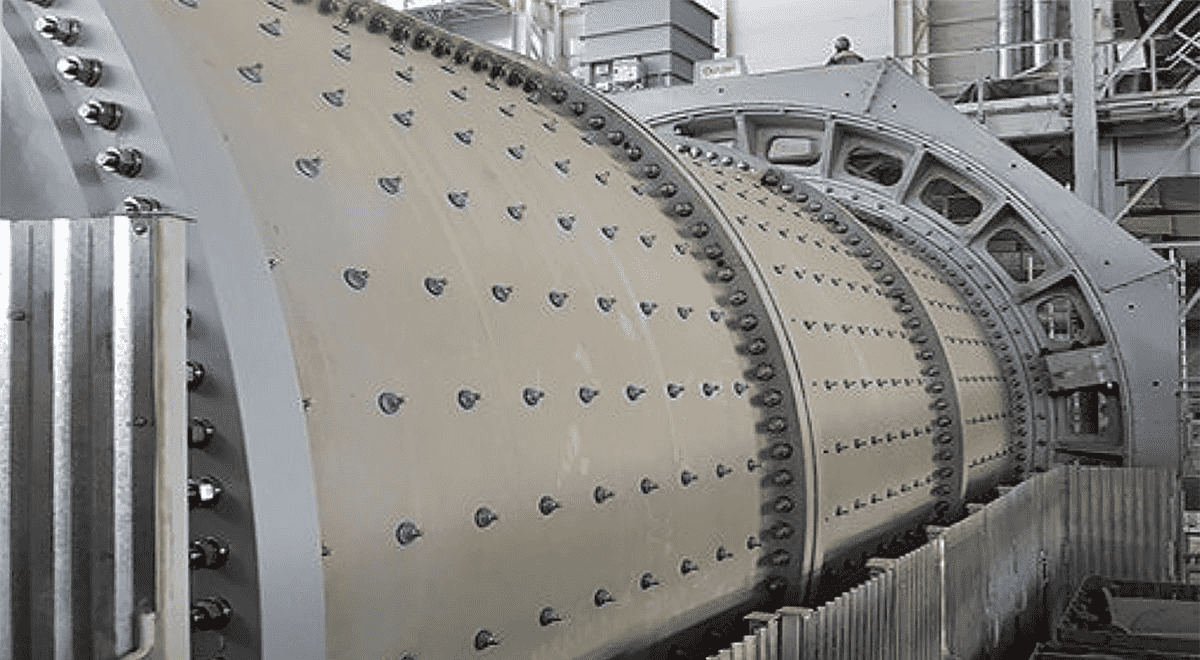

Ball mills are essential equipment in many industrial processes, from mining to materials engineering, primarily used to grind materials into finer solid-state particles. The success of these mills largely depends on the grinding media utilized within them. This article seeks to illuminate the functionalities and efficiencies of ball mills, focusing on the role of grinding balls, types of ball mills, factors influencing milling efficiency, and safety considerations involved in the process. Whether you're searching for mill balls for sale or seeking to understand the finer details of ball milling, this detailed guide offers substantial knowledge.

The fundamental mechanism of ball milling is grounded in its ability to transform large, coarse materials into fine particles through mechanical attrition. The process involves rotating a ball mill containing various sizes of hardened spheres, often made from steel or cast iron balls, which impact and grind the material.

This method thrives on the interface between the rotating drum and the grinding media as they cascade over the material, leading to pulverization and blending. Different conditions such as the size and type of grinding balls, drum rotation speed, and material density play crucial roles in influencing the outcome of this process.

Parameter | Impact on Milling |

Ball Size | Larger balls impact more forcefully but may provide less surface area for finer grinding. |

Drum Rotation Speed | Critical speed is needed to ensure the balls are lifted and cascade properly for optimal grinding. |

Material Density | Denser materials require more energy to grind effectively. |

The role of grinding balls in the ball milling process cannot be overstated. Grinding balls not only assist in achieving the desired material size reduction but also play a critical role in energy transfer and heat generation within the milling components.

Over time, steel balls or chrome balls might undergo changes due to consistent impact and friction, necessitating procedures such as heat treatment in heat treatment furnaces to restore their hardness and efficiency. These methods ensure that the steel ball maintains its optimal performance, avoiding premature wear and tear within the grinding media environment.

There are various types of ball mills, each designed to cater to specific industrial needs and material handling capabilities. Some of the prevalent types include:

Planetary Ball Mills: These are suitable for finely grinding a variety of materials and ensuring homogeneity within mixtures.

Horizontal Ball Mills: Widely used in industry for large-scale processes, they offer solutions that require heavy-duty handling.

Vibratory Ball Mills: Enable high-frequency motion, ideal for particle distribution and small scale applications.

Each mill type requires distinct grinding media, set parameters, and often the use of a casting furnace or an induction melting furnace for the preparation of mill balls or grinding balls that are appropriately tailored to the milling needs.

Several parameters might influence the efficiency and effectiveness of a ball milling operation. Manufacturers and engineers continually seek to optimize these to ensure high productivity and minimal resource waste. Factors such as:

Mill Speed: Operated below critical speed to enhance contribution from the grinding media.

Material Load: Optimum load needs to be calculated to facilitate sufficient contact between the equipment and material.

Grinding Media Quality: Choosing the right grinding media, such as forged steel balls or cast iron molds, is necessary to impact hardness and maintain efficiency.

While ball mills are integral to industrial grinding, they pose certain risks necessitating awareness and safety considerations. Ensuring your equipment, such as quenching furnaces and foundry furnaces, complies with operational safety standards is paramount. Safety measures may include:

Regular Maintenance: Routine checks for equipment soundness and heat treatment machines for high-temperature processes.

Protective Gear: Adequate protection for personnel handling the equipment.

Dataset Analysis: Regularly monitoring data for unusual patterns indicating machine faults or safety lapses.

Through educating employees and enforcing robust safety protocols, the potential risks associated with improper handling of milling balls and auxiliary equipment can be significantly reduced.

The nuanced operation of a ball mill, specifically the role of grinding media, is essential for achieving high-quality results across various industries. By understanding the basic principles, optimizing operational factors, and adhering to stringent safety protocols, companies can capitalize on ball milling's full potential. As you delve deeper into acquiring the right mill ball, whether from mill balls for sale or through custom orders, ensure you remain informed and vigilant to derive authentic worth from your investment. For comprehensive, high-quality milling solutions and ball mill balls for sale, our brand delivers trusted performance tailored to your unique needs, enhancing both efficiency and output.

We assured you that your personal information will be kept confidential. The personal data we collect is only used to process your inquiry.